GRP Tanks

From Water to Chemicals, from Food to Effluent – most liquids can be safely and economically stored in GRP tanks.

GRP Tanks, Vessels & Silos

GRP (Glass Fibre Reinforced Plastics) storage tanks are generally accepted as best practice for installation throughout most industries.

Further to our standard range of sizes, these can be custom designed in a variety of resin/glass fibre laminates, including Isophthalic, NPG Isophthalic & various Vinyl Esters.

Typical applications include water and corrosive liquids such as sewage sludge, general effluent, liquid fertiliser, brine and aggressive chemical storage.

Offering a wide selection of standard sized GRP composite (Glass Reinforced Plastic) flat based tanks.

- Available from 5,000 – 160,000 litres capacity

- Available diameters: 2000mm, 2400mm, 3050mm, 3500mm & 4111mm internal

- Very strong yet light in weight

- Available with sloping base

Specifically designed for the most economical use of materials via semi-automated manufacturing techniques to ensure low cost, competitive products.

Bulk water storage firefighting tanks.

- Capacities from 50m³ to 200m³

- Tanks are built to Category 1 to BS 4994 & can be certified by a third party insurance inspection if required.

- Only requires drain down inspection every 10 years

- Designed & built to the requirements of the Loss Prevention Standard LPS 1276.

For use with automatic fire protection sprinkler, mist and wet risers – saving lives & property from fire.

Most systems require one or more bulk water storage tank for the pumps to call upon to deliver the water for immediate supply to the fire pumps.

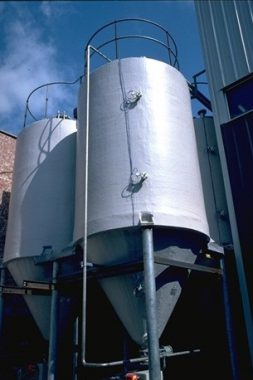

A superb standard range of high performance GRP silos.

- Strong and light in weight

- Completely corrosion free

- One piece body with a smooth interior assures complete emptying

- Smooth knuckle with no internal crevices.

Typical applications include: sugar, PVD salt, animal feeds, fertilisers and other granular products.

From our UK-based factories we fabricate tanks using various materials and manufacturing processes. With a post-curing oven of over 5 metres in diameter and 13 metres long, Forbes is able to carry-out the full immersion post-cure of even the largest of tanks.

We can ensure the perfect fit whatever our customers’ requirements and have for many years supplied industry with a wide range of high specification products.

Forbes is able to offer a full range of on-site services to suit all budgets. From the simple offloading and positioning of tanks and equipment to a full project managed turnkey services.

Speak to our sales team to find out more.

(0)1366 389600

sales@forbesgroup.co.uk